Introduction

This calculation methodology is based on the 2020 ASHRAE Handbook – Systems and Equipment, Chapter 26. This methodology assumes that the air handling unit (AHU) uses a variable speed supply fan, and that the energy recovery component is a rotary wheel.

Calculator

The following calculator is used to estimate a full year of sensible and latent heat transfer in an energy recovery ventilation (ERV) system:

Measurements

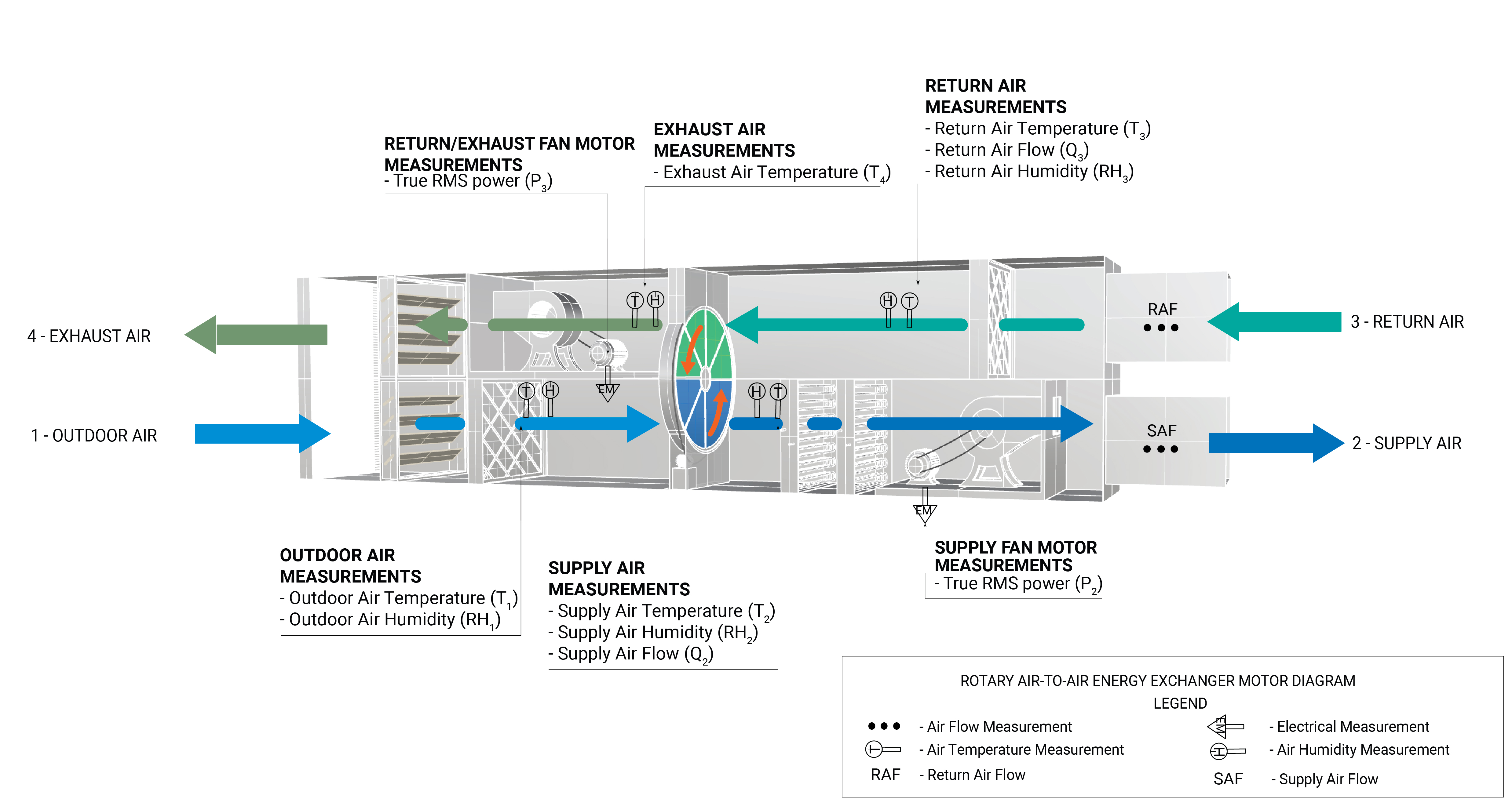

This methodology works with hourly data only and each measurement is taken at the start of the hour for a minimum duration of six weeks. If the ERV system is used during both the heating and cooling seasons, then six weeks of data per season is needed. Data is used to calculate heat transfer for the measurement period first, then is extrapolated to a full year. Measured data is obtained via the following measurement techniques:

Measurement points are shown in Figure 2 and the variables to measure are listed in Table 2.

Air-to-air Heat Exchanger Calculations

Section A.1 describes how to calculate the sensible and latent heat transfer for the duration of the measurement period. If six weeks of data is collected, then heat transfer will be calculated for each hour interval for those six weeks. Sensible and latent effectiveness are a measure of the performance of the ERV system. Effectiveness is the actual heat transfer divided by the maximum possible heat transfer by the heat exchanger. These values are calculated in section A.1 for each hour interval and are used in section A.2 to estimate the full-year heat transfer.

To calculate latent heat transfer and effectiveness, first the humidity ratio

| Relative Humidity (%) | Humidity Ratio Equation |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Where,

To estimate heat transfer for a full year, simple linear regression (used to assess the relationship between two variables) is performed in Microsoft Excel using the LINEST function. These calculation steps are described in more detail in Section A.2.

Section A.3 describes how to calculate the electrical energy consumption of the supply and return fan motors using hourly power draw data. The hourly data is used to develop an average hourly schedule of both fan motors for all seven days of the week as a proxy of the occupancy schedule of the facility. This occupancy schedule is used in Section A.2 to conduct the simple linear regressions.

A.1: Heat Transfer for the Measurement Period

The following methodology is used to calculate the sensible and latent heat transferred by the ERV system during the measurement period only. Sensible and latent effectiveness are also calculated in this process. All data used in section A.1 should rely on data being measured with either data loggers or BMS historical trends. Measured data used in this section is summarized in Table 3.

|

Hourly Measured Values |

|

|

|

Temperatures (F) |

|

|

Relative Humidity (%) |

|

|

Air flow rate (ft |

|

|

Fan motor Power (kW) |

- Calculate the mass flow rate of supply air leaving the ERV for each hour interval.

Where,

- Calculate the mass flow rate of return air entering the ERV for each hour interval.

Where,

- Calculate the humidity ratio for outside air entering the ERV (

Where,

- Calculate sensible heat transferred by the ERV for each hour interval.

Where,

- Calculate latent heat transferred by the ERV for each hour interval.

Where,

- Heat transfer should be calculated only when the energy/heat recovery mode is on. This can be determined by checking the temperature difference across the recovery system in both the supply-air side and the return-air side. Another condition is that the supply fan motor must be running for heat transfer to occur. Sometimes the ERV is off and the supply fan motor is on. In this scenario, we cannot assume heat transfer occurs.

Where,

Where,

Where,

Where,

Sensible and Latent Heat Effectiveness

Sensible and latent heat effectiveness has the same conditions as heat transfer where effectiveness should be calculated only when the energy/heat recovery mode is on and the supply fan motor must be running.

- Calculate the latent effectiveness for each hour interval.

Where,

- Calculate the sensible effectiveness for each hour interval.

Where,

A.2: Heat Transfer for the Full Year

To estimate the full year heat transfer, the occupancy patterns and schedule defined in the measurement period are extrapolated to the entire year. Supply air flow (Q2), return air flow (Q3), and sensible and latent effectiveness are calculated by performing a regression analysis with the variables listed in Table 4. Regression analysis plots data on a graph and generates a line that traces the distribution of data. The line has a formula associated with it and the formula is used to project the dependent variable for the full year. To accomplish this, the Microsoft Excel function LINEST is used with the values in Table 4.

|

|

Independent Variable |

Dependent Variable |

|

Regression 1 |

|

|

|

Regression 2 |

|

|

|

Regression 3 |

|

|

|

Regression 4 |

|

|

Regressions 1 and 2

There is a cubic relationship between fan motor power draw and air flow rate. The equation that describes the relationship between these variables is:

Where,

With this formula, the air flow rate Q2 and Q3 can be projected for the full year by plugging in values for x, the supply fan motor power draw.

Regressions 3 and 4

These steps yield an assessment of the relationship between the measured air flow rate of supply air leaving the ERV system (Q2) and the sensible and latent heat effectiveness that was calculated in section A.1. The relationship between air flow rate and effectiveness is linear, and the equation that describes the relationship is:

Where,

The values of

Where,

After projecting the airflows and effectiveness rates to a full year, the next step is to calculate the hourly mass flow rates and humidity ratios for a full year.

- Calculate the mass flow rate of supply air leaving the ERV for each hour interval for the entire year.

Where,

- After projecting the airflows and effectiveness rates to a full year, the next step is to calculate the hourly mass flow rates and humidity ratios for a full year.

Where,

- Calculate the humidity ratio for outside air entering the ERV (W1). In this step, the hourly climate normal year (CNY) outside air temperature (OAT) and relative humidity data is used with the equations in Table 1 to determine the humidity ratio for that hour. In this same step, the units are converted from grains/lb to lb

Where,

- Estimate the hourly humidity ratio of supply air leaving the ERV for the full year. In this equation, it is assumed that the latent heat of vaporization is constant.

Where,

- Estimate the temperature of supply air leaving the ERV for the full year. In this equation, it is assumed that specific heat of air is constant.

Where,

CUNY BPL assumes that T3 and W3 are constant values, reasoning that occupants will want the same indoor air temperature, regardless of the season. It is up to the heating and cooling plants to maintain that setpoint temperature. The next step is to calculate sensible and latent heat transfer.

- Calculate sensible heat transferred by the ERV for each hour interval for the full year.

Where,

- Calculate latent heat transferred by the ERV for each hour interval for the full year.

Where,

- Heat transfer should be calculated only when the energy/heat recovery mode is on. This can be determined by checking the temperature difference across the recovery system in both the supply air side and the return air side, and air flow rate across the heat exchanger. Air flow happens when the supply fan motor and exhaust fan motor are on. Sometimes the ERV rotary wheel is off and air flow bypasses the rotary wheel when the supply fan motor is on. In this scenario, we cannot assume heat transfer occurs.

Where,

Where,

Where,

Where,

A.3: Annual Supply Fan Energy Consumption

This calculation methodology assumes the power draw of the supply and exhaust fan motors is measured using a power logger at one-hour intervals over a minimum of six weeks. The power logger measures all three phases of the panelboard to capture accurate data. The process begins by calculating three-phase power using the provided formulas. The dataset is then condensed into an hourly schedule for all seven days of the week to determine when heat transfer occurs. Finally, this schedule is extrapolated to represent a full year, resulting in an estimate of the annual energy consumption of the fan motors.

- Calculate the hourly three-phase power draw of the motor by summing the single-phase power of each electrical line for each hour interval.

Where,

- Calculate average energy consumption for each hour of the week. This step generates an hourly schedule for a week, and this schedule is used to calculate the full year heat transfer. In this step, the hourly power draw (kW) gets converted to hourly energy consumption (kWh) because data is in one-hour intervals2.

Where,

- Calculate average daily energy consumption for a given day of the week.

Where,

- Calculate the average energy consumption per day for weekdays.

Where,

- Calculate the average energy consumption per day for weekend days.

Where,

- Calculate the annual weekday energy consumption (Worksheet: “Step 4. Results,” cell E3).

Where,

- Calculate the total weekend energy consumption (Worksheet: “Step 4. Results,” cell E6).

Where,

- Calculate the total annual energy consumption of the motor.

Where,

- Calculate the total annual energy consumption of the supply and exhaust fan motors.

Where,

Further Reading

-

For general information on Option A M&V guides, please read section 4.2 (starts on page 23) of “M&V Guidelines: Measurement and Verification for Performance-Based Contracts Version 4.0” from the U.S. Department of Energy: https://www.energy.gov/sites/prod/files/2016/01/f28/mv_guide_4_0.pdf#page=23

-

ASHRAE (2020) “2020 ASHRAE Handbook-HVAC Systems and Equipment” Chapter 26.

-

CUNY Building Performance Lab (May 2020). “Quantification of Energy Savings from Implementing Building Re-tuning Recommendations.” (pp. 21–22). New York, NY: Department of Citywide Administrative Services.