General Overview

A waterside economizer is used to fully or partially cool the chilled water without mechanical heat transfer when outdoor air temperatures are cold enough to meet the building’s cooling demand. Typical waterside economizer systems have an external heat exchanger; however, the chiller itself may occassionally be set up to perform the function of a waterside heat exchanger.

Components

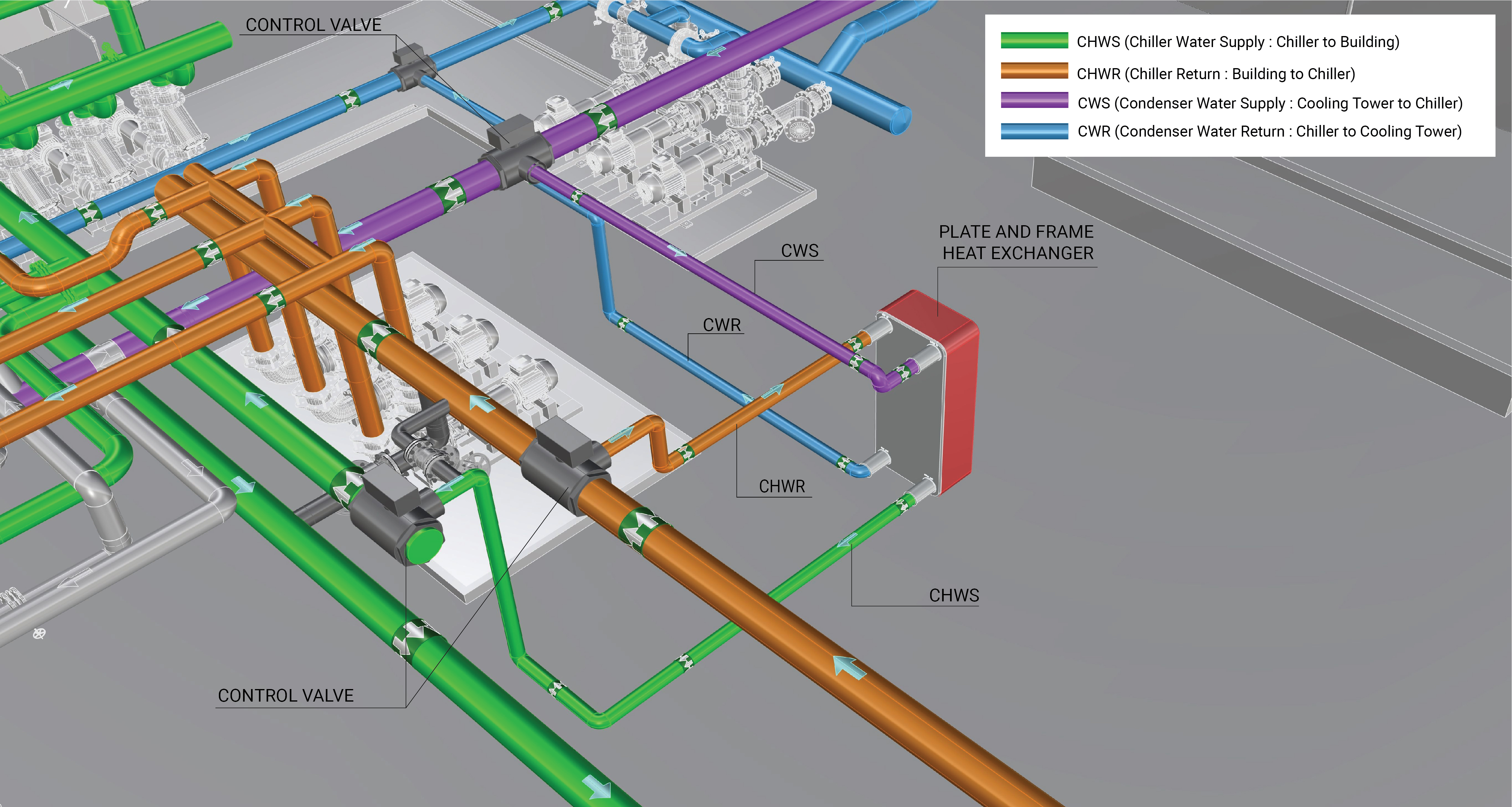

The components associated with a waterside economizer are heat exchanger, piping, and valves. These components are shown in Figure 1.

External Heat Exchanger

Typical heat exchangers installed in waterside economizers systems are plate and frame heat exchangers. They can be configured as integrated and non-integrated economizers. The non-integrated configuration consists of a plate-and-frame heat exchanger (PFHX) in parallel with chillers and requires the heat exchanger to supply the entire cooling load. An integrated configuration, the PFHX are arranged in series, allowing the chiller to utilize pre-cooled chilled water and minimizing the energy required by chillers. Learn More

Piping, fittings, and valves

Piping can have different arrangements to allow the desirable operation of the waterside economizer.

Evaluation of Energy Consumption

The primary effect of waterside economizer is the savings in electricity usage at plant level to meet the cooling load of the building. For more information about the energy consumption of the overall water-cooled chilled water plant, see the Water-Cooled Chilled Water Plant.

The cooling energy savings are equivalent to the heat rejected through the waterside economizer. Table 1 provides a summary of the components to measure to arrive at values needed to quantify the heat rejected from the chilled water to condenser water by free cooling.

| System Quantification | Values to be Quantified | Energy Consuming Components | Measurements |

|---|---|---|---|

| Waterside economizer heat rejection load |

|

Heat exchanger of waterside economizer |

Measurement Locations

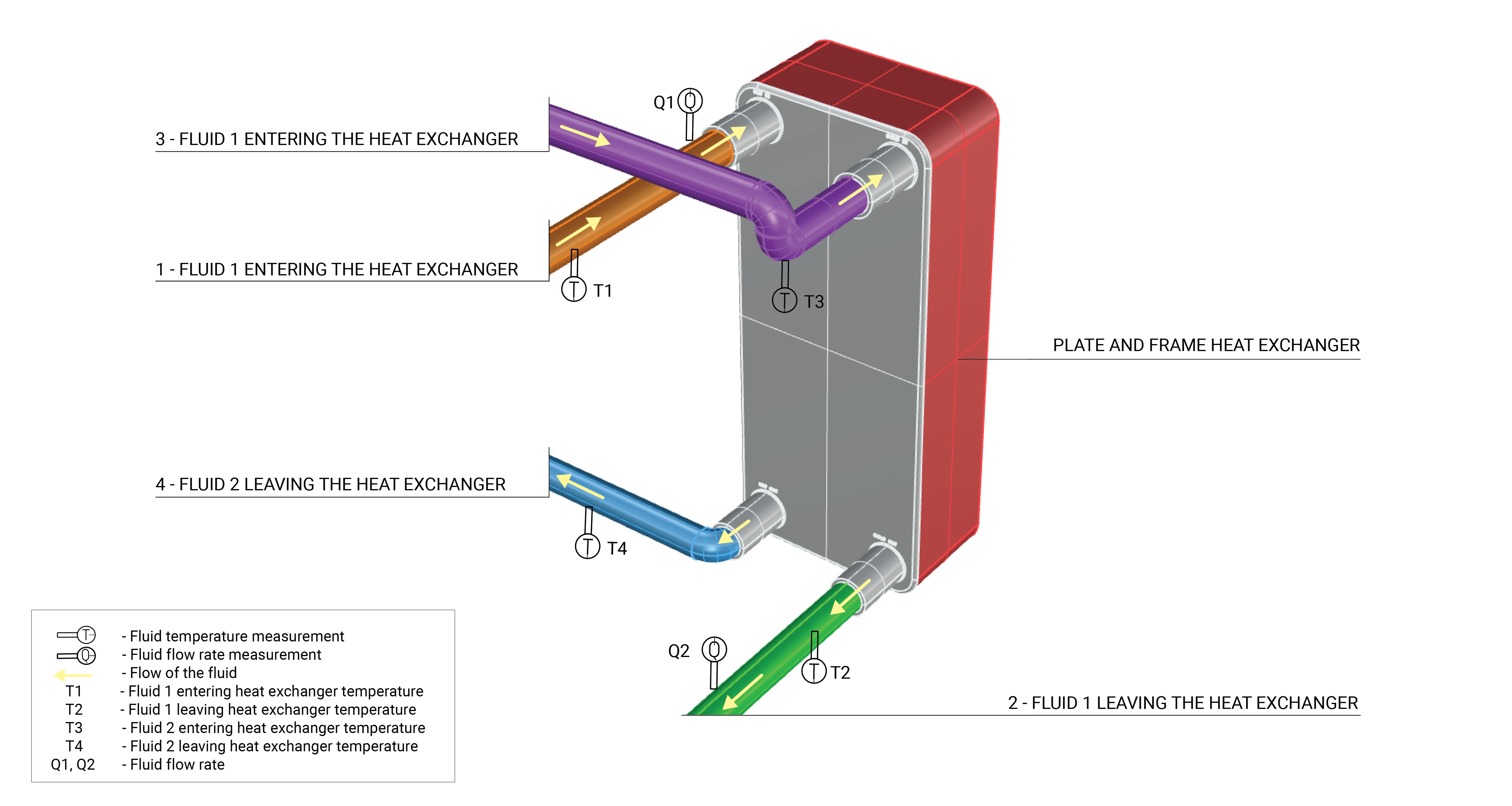

The measurement locations for the waterside economizer are schematically shown in Figure 2:

Further Reading

-

ASHRAE (2019). “ASHRAE Handbook: HVAC Applications,” Chapter 48. DESIGN AND APPLICATION OF CONTROLS. I-P Edition.

-

ASHRAE (2020). “ASHRAE Handbook: HVAC Systems and Equipment,” Chapter 40. COOLING TOWERS. I-P Edition.

-

Taylor, S (2014). “How to Design & Control Waterside Economizers,” ASHRAE Journal, Vol. 56, No 6. American Society of Heating, Refrigerating and Air Conditioning Engineers; pp: 30-36.

-

Trane Engineers Newsletter (2016). “Waterside Economizers - Keep the ‘Free’ In Free-Cooling.” Trane, 2016. https://www.trane.com/content/dam/Trane/Commercial/global/products-systems/education-training/engineers-newsletters/waterside-design/ADM-APN058-EN_06012016.pdf.