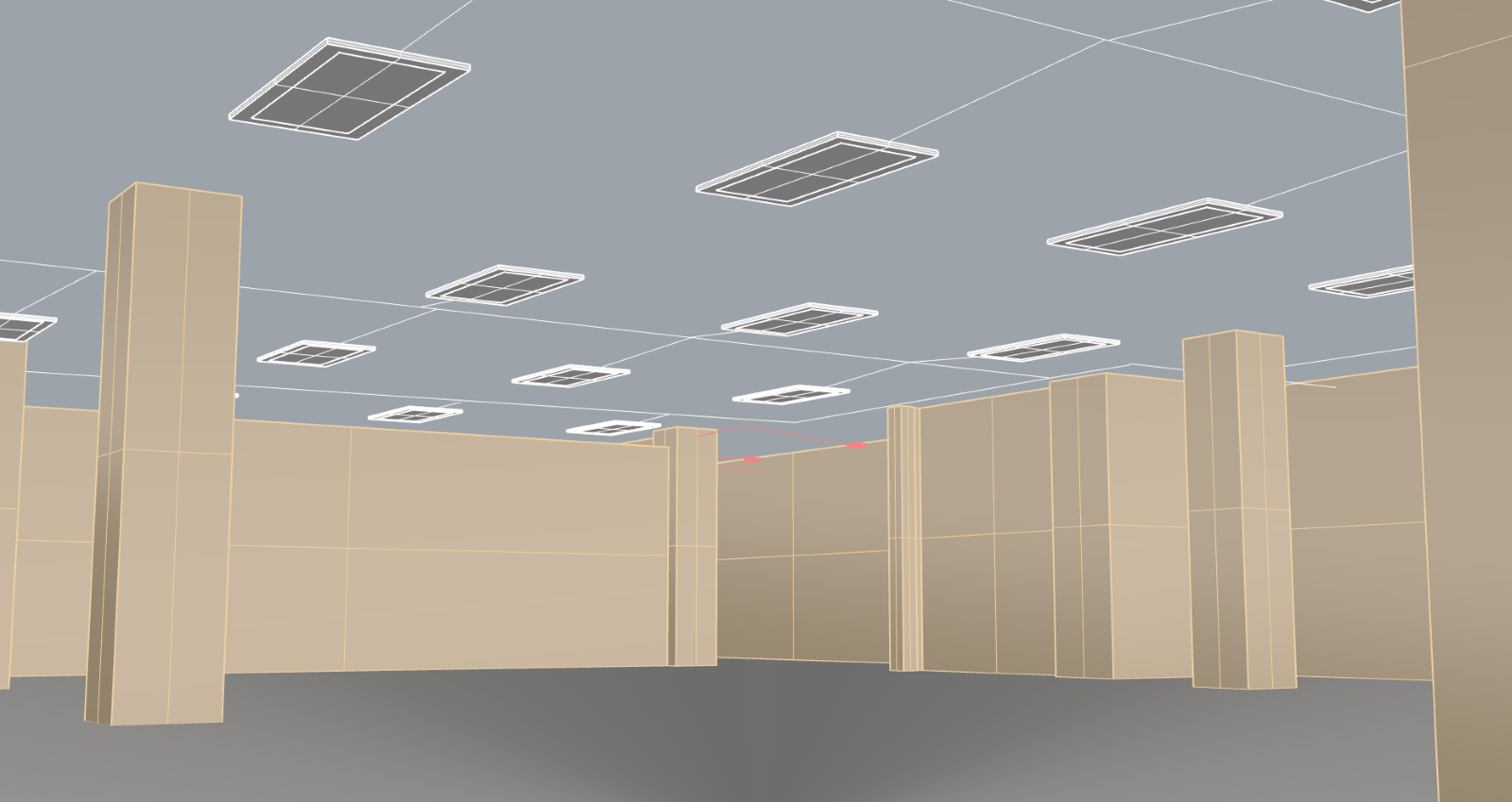

General Overview

A lighting fixture system produces light to illuminate a specific area or areas. Current is received from the electrical distribution system. The group of fixtures that comprise a lighting system can be configured in many ways with different lamp types. A building can have one or more lighting fixture systems. The main components of an individual lighting fixture are lamps, ballasts, and controls.

Components

Lamps

Lamps refer to the enclosure of a lighting source. The most common types of lamps are incandescent, fluorescent, high intensity discharge (HID), induction, and LED. Many types of lamps can be used within a facility. All lamps convert electrical energy to light, with some energy converted to heat as well. The efficiency of the lamp in minimizing losses to heat is the biggest determining factor in the energy efficiency of the lighting fixture system. In addition to electrical efficiency, different lamps produce different color spectrums, which are better suited to different applications. For example, an office typically requires white light with a “cool” tone. However, warehouse lighting may be more yellow or orange without impacting its function.

Ballast

A ballast is an electrical device that regulates the voltage and current supplied to a lamp. While incandescent lamps do not require ballasts, all other lamp types need them to ensure stable operation. Ballasts come in various types, each designed for specific lamps, and some fixture systems have ballasts integrated into the lamp component. The regulation of voltage and current results in some energy loss as heat, and ballast efficiency varies depending on how well these losses are minimized.

Housing

The fixture housing is the physical receptacle that houses the lamp and ballast. The housing may include shutters or diffusers that direct and disperse the light. Some housing is designed to disperse the heat generated by the lamp and ballast more effectively, which increases the life of the fixture.

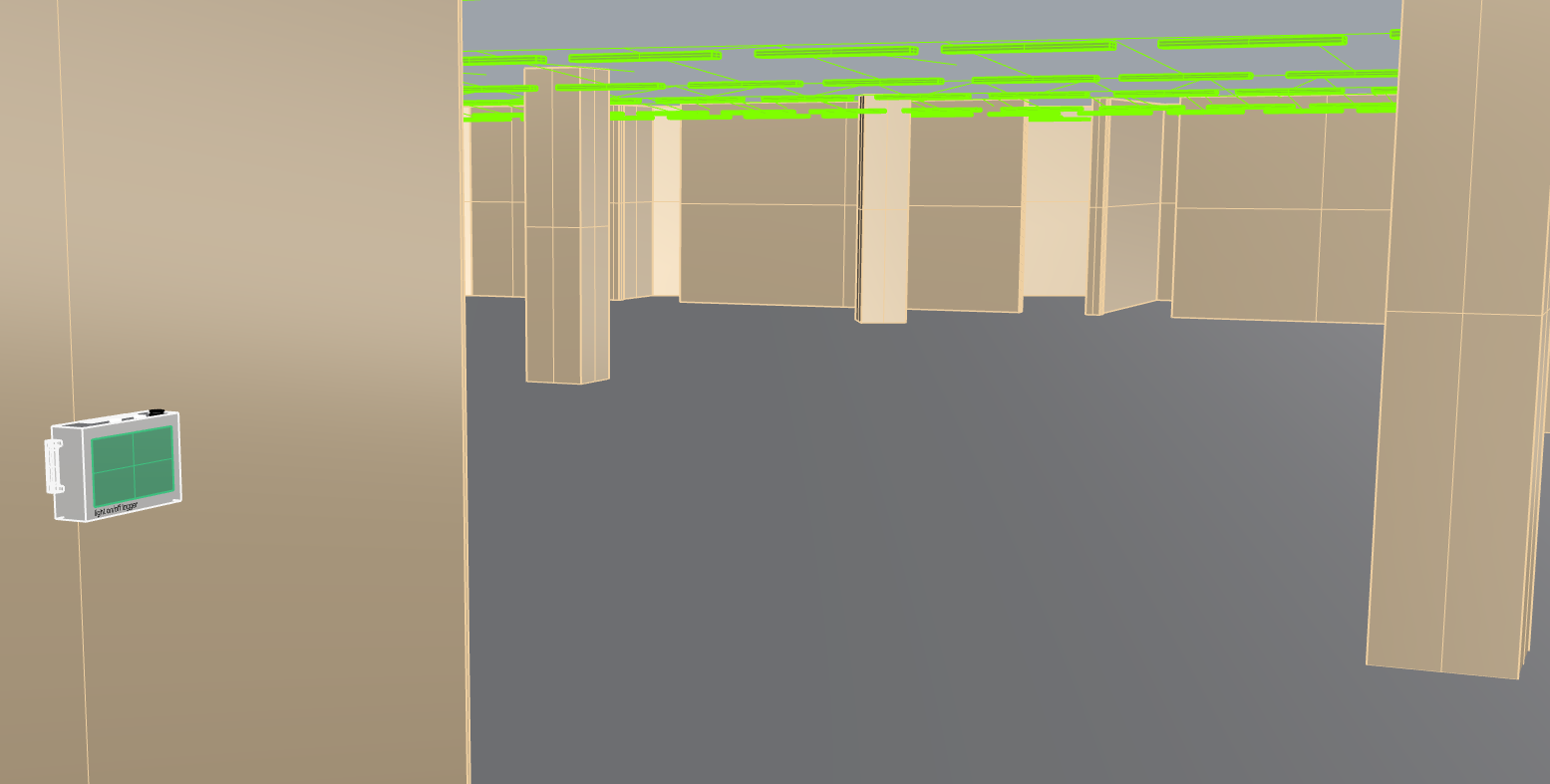

Controls

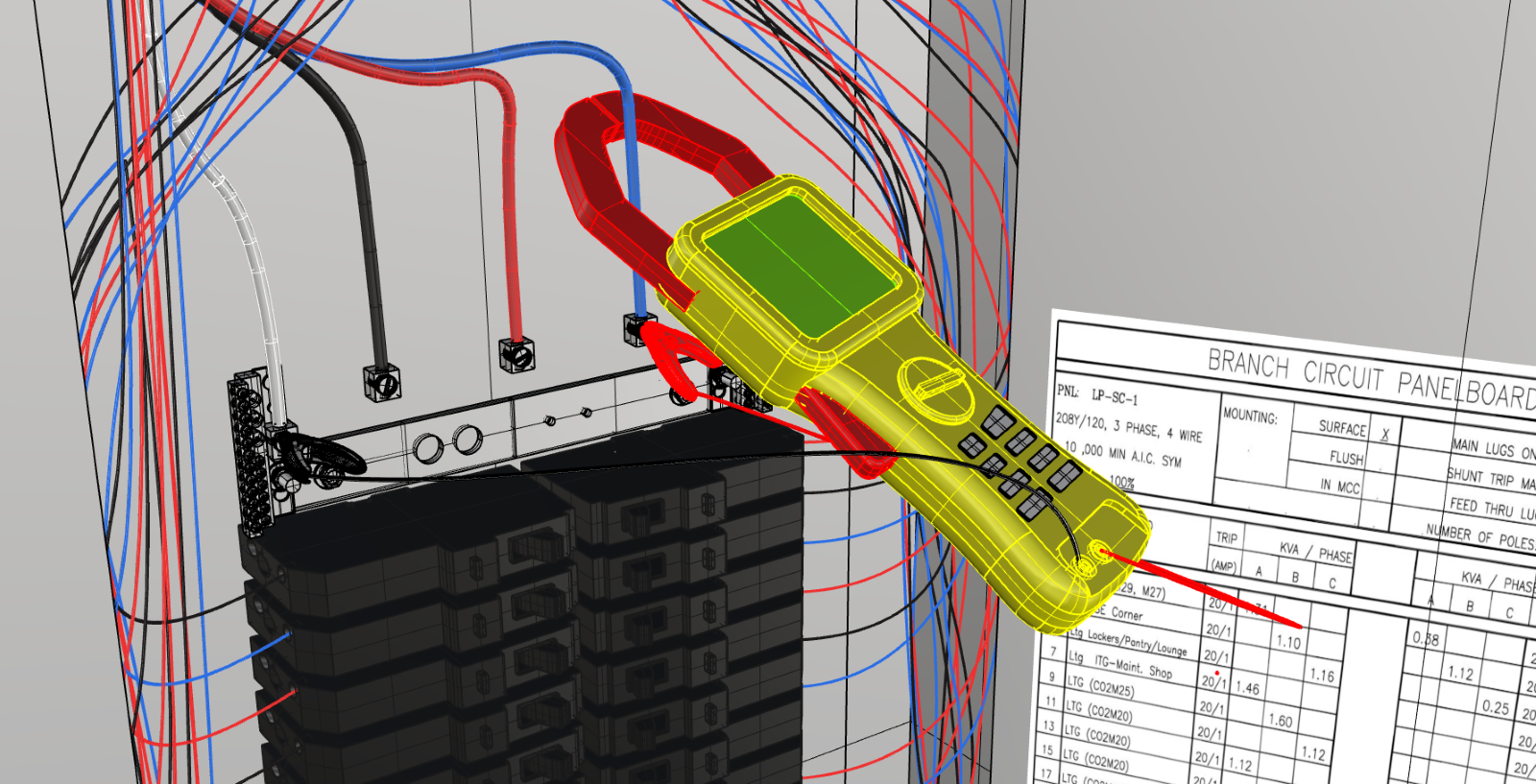

Controls regulate the operation of the light fixtures, such as when they are turned on and off, and their brightness. Controls can be manual or automatic. Manual controls are wall switches within a space and circuit breakers at the electrical panelboard and switchgear. Automatic controls use sensors and/or timers to determine when and how to regulate the fixture operation. The two most common sensors used in lighting controls are motion sensors, which approximate when a space is occupied or vacant, and daylight sensors, which determine when natural sources are providing enough light for the fixtures to be turned off or dimmed. Some automatic controls have their own control panel that is wired directly to the circuits at the lighting panelboards or the ballasts of individual fixtures.

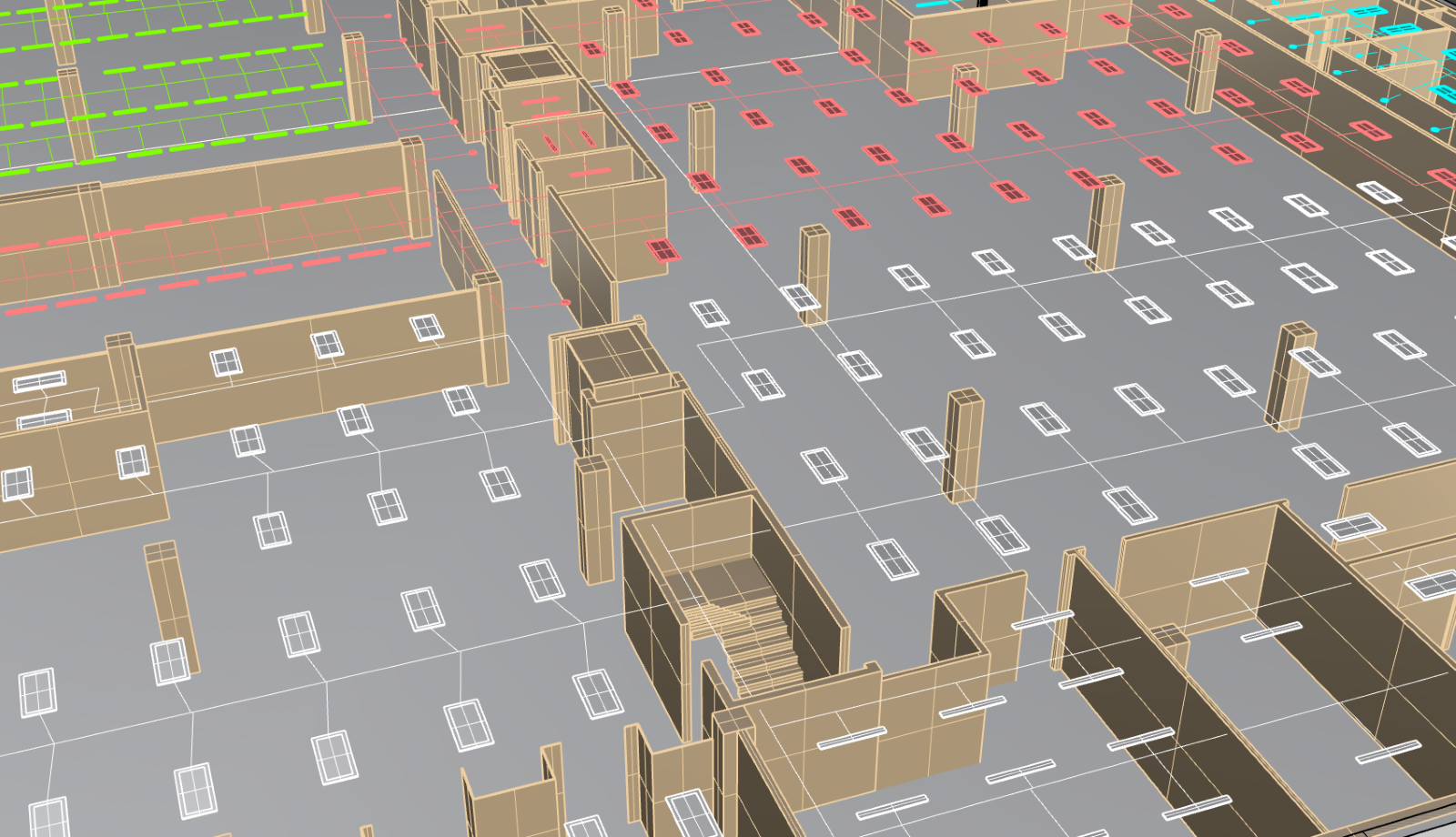

Measurement Locations

Electrical measurements of lighting fixtures must be taken at the electrical distribution components. Further details can be found in the Electrical Distribution system page.

An auditor can develop a sampling plan and use a light on/off logger to measure the schedule of a single fixture. The single light fixture should be representative of the other fixtures in the room to assume the same schedule for all fixtures. Then, a direct power draw measurement at the electrical panelboard that serves the fixture is needed. The power draw data and the schedule data obtained from the light on/off logger allows an auditor to estimate energy consumption.

What and How to Measure

Perform the following measurements to quantify the energy consumption and operating characteristics of a lighting fixture system:

Measurement Equipment

If you are NYC agency personnel and you’re already familiar with the measurements above, the Field Equipment Lending Library has put together a kit wit all the equipment needed for measuring this component:

Lighting kit

Use this kit to measure the electricity consumption of a lighting system.

Energy Consumption Quantification

Electricity is the energy source for all modern lighting systems.

How to Quantify

The following downloadable file(s) can be used to calculate energy consumption based on the measurements taken for a lighting fixture system:

Further Reading

- California Energy Commission (June 2015). 2016 Building Energy Efficiency Standard for Residential and Nonresidential Buildings, Title 24, Part 6, Chapter 6: Residential Compliance Manual, CA: California.